Mechanical Engineering

Mechanical Engineering

The research subject of mechanical engineering has a direction towards product development and focuses on how a digital and model-driven work method in technical product development can lead to innovations that fit into a sustainable society.

Introduction

Perspective areas are innovative engineering design methodology, simulation-driven design, and model-based development, which requires methods and tools that enable product developers to efficiently, and in as early stage as possible, be able to predict, describe, assess, and improve product characteristics. Design, development, analysis and simulation methods are needed for the prediction of technical product properties as a function of different combinations of design variables of the product life cycle. Broad or specialized engineering skills in a number of disciplines, and simulation is needed for the prediction of technical product properties as a function of different combinations of design variables as well as for the prediction of economic and socio-ecological impact of product life cycle.

An overarching objective is that when needed, be able to integrate all the relevant methods and tools for product development capability in business leaders and product developers ordinary working environment. Advanced IT tools, for example, analysis, modeling, simulation, visualization, optimization, product data management, and distributed engineering related to experimental methods are characteristic of the research.

Examples of special areas currently being studied and used for product improvements are value-driven development models, knowledge engineering methods, mechanical and mechatronic systems; structural dynamics; and fracture mechanics.

Research in mechanical engineering is mainly conducted at the Department of Mechanical Engineering.

News

Specialisation

Research Specialisation

Within the technological research field mechanical engineering you find the following research aspects:

- Innovation engineering

- Design automation

- Creative concept generation

- Lean product development

- Model Driven Development

- Product-Service systems and innovation

- Product development methods and tools

- Simulation driven product development

- Structural analysis

- Value driven development

The research is carried out int the PDR Lab – Product Development Research Lab, led by Professor Tobias Larsson and Professor Marco Bertoni, is using a strategy of creative problem solving at an early stage and digital computer simulations to generate ideas, create, appreciate, model and drive the development of intentional product-service systems in an industrial context, hence we call this simulation-driven design (SDD) Product Innovation (PI ) with a focus on product-service systems (PSS). The research helps companies meet the complex challenges when moving towards a situation where they need to develop greener products and services to be sustainable. This places new demands on the engineers involved in product development. They get more and more aspects and options to consider all the time, sustainability is one of the factors.

Our study programmes are given in close collaboration with our research and our collaboration companies to ensure that “the engineer’s desktop” is up-to-date and updated with tools and methods.

The goal is to conduct research on, develop and implement this updated “Engineering Toolbox 2.0” for the future of engineer, and to support collaborative companies to take advantage of, and implement the results.

Examples of public funding:

KKS, VINNOVA, the EU, Swedish Agency for Economic and Regional Growth and Region Blekinge.

Examples of partners:

GKN Aerospace Engine Systems, Volvo Construction Equipment, Kockums, DIAB, TetraPak och Dynapac.

Read more about our research/education/collaboration efforts within the scope of Mechanical Engineering:

Quote from a partner

Our collaboration with BTH is a real win/win partnership. Our company is in a very exciting transformational phase which gives BTH good examples for their research. Since BTH collaborates with other industries that have already done their shifts from products to services, for example, we can gain knowledge about proven methods instead of inventing everything ourselves.”

Jenny Elfsberg, Director of Emerging Technologies at Volvo Construction Equipment.

Applied fracture mechanics in package openings

One goal of the project is to create a better understanding of the characterisation of the functional behaviour of packaging and materials – e.g. technical parameters and continuum mechanics of material properties – through experimentation and simulation. With a better understanding of the fracture mechanics of packaging, new and better packaging can be developed.

Partner/funder: Tetra Pak Packaging Solutions AB

Contact person: Sharon Kao Walter

ASPECT – A System for Electric and Connected Transport Solutions

Project ASPECT aims to, based on learnings from pilot Electric-Site, lift the technology to an energy optimized solution to scale in both volume and size. Focus for this project is within confined area. The project includes design of energy infrastructure, electric system on machines and site management system. Furthermore it includes validation of digital infrastructure for system, method and requirements on infrastructure, digital twin for energy optimized system and to understand if it is possible to increase energy efficiency by using teleoperation.

Partner/funder: BTH | Ericsson AB | Göteborgs University | Telia Sverige AB | Volvo Autonomous Solutions | Voysys AB | VINNOVA FFI

Contact person: Tobias Larsson

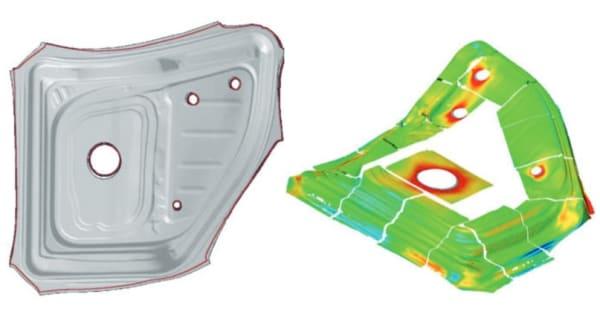

PREDICT

The purpose of PREDICT is to achieve increased accuracy in failure predictions by developing advanced material models, calibration techniques and effective finite element simulations, which can enable unambiguous and reliable formability predictions. Specially, simulation failure predictions of phenomena such as non-linear strain paths, effect of strain rate, anisotropy and presence of edge cracks will be studied. Failure experiments will be performed, and characterization techniques will be developed to generate advanced FE-models that can easily be integrated to industry practice. Finally, FE- simulation driven metamodels based on AI will be developed to predict formability based on supplier data to make process adjustments for failure prevention. This will be an important step towards Industry 4.0 for the partners.

Partner/funder: BTH | Alfa Laval | RISE IVF | Scania CV | SSAB EMEA | Volvo Cars | Volvo Trucks

Contact person: Md Shafiqul Islam

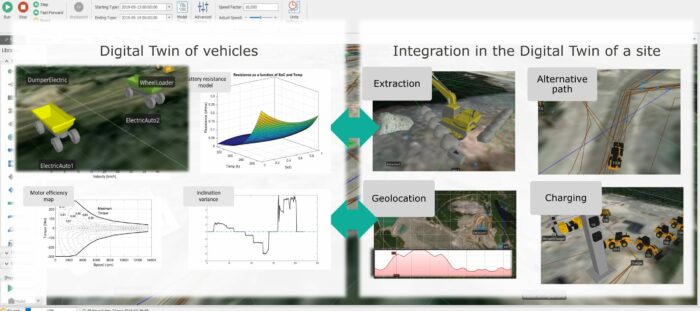

eTWIN – Digital-Twin enabled Transition into Electromobility and Autonomy in Construction Equipment

This project has demonstrated the capabilities of creating a digital twin of typical mining operations by combining the simulation of the energy consumption and performances of single electrical vehicles with specific productivity requirements and topographic configuration of the overall mining site. This allows the evaluation of the economic and environmental impact of the transition toward electromobility in mining, as well as supports the requirements definition for electrical vehicles.

Partner/funder: BTH | Volvo Construction Equipment | VINNOVA

Contact person: Associate Professor Alessandro Bertoni

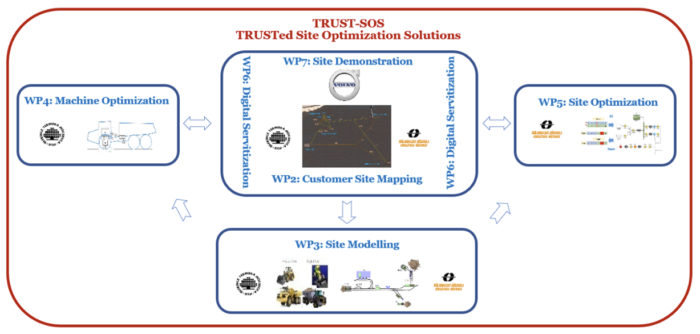

TRUST-SOS – TRUSTed – Site Optimisation Solutions

In the project TRUST–SOS, we are developing digitalized services to increase the level of trusted decision making to optimise overall site systems in off-road transport applications. Today, off-road sites and fleet operations involve a high degree of experience-based decision making to create the optimal usage of equipment and resources at the site and to reduce inefficiencies.

Partner/funder: BTH | Mälardalen University | Volvo Construction Equipment | VINNOVA FFI

Contact person: Tobias Larsson

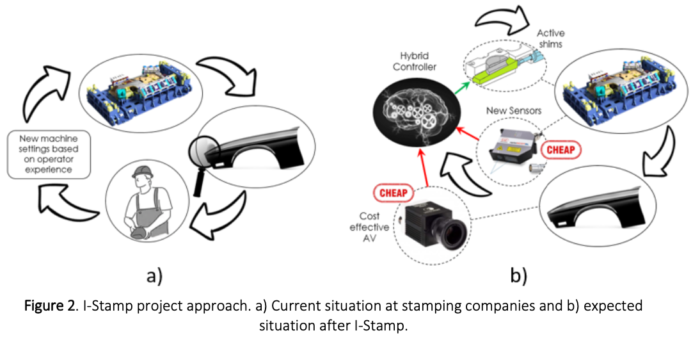

I-Stamp – Intelligent and sustainable stamping processes using hybrid control strategies together with process monitoring

The machine tool investment for stamping (presses and tools) is cost intensive in the automoti The machine tool investment for stamping (presses and tools) is cost intensive in the automotive sector. Maximizing return on investment (ROI) against these assets is crucial for maintaining a healthy bottom line. Additionally, minimizing the amount of scrap is necessary to become more competitive and create more sustainable manufacturing processes.

In this context, I-Stamp project aims at drastically increasing the OEE (overall equipment effectiveness) of automotive big size press-lines applied for the production of large critical outer components and high strength inner reinforcements by implementing new digital solutions.

Partner/funder: BTH | Fagor Arrasate | Ford Espana | Rise IVF | Volvo Car Corporation | PDS Engineering | Tata Steel International | Mondragon University | VINNOVA | EU

Contact person: Tobias Larsson

Electric infrastructure creation

The goal is to demonstrate technology solutions to be able to operate larger infrastructure construction 100% emission-free by electrifying participating mobile machines. The solution will probably involve process changes and part of the project is to investigate how these can be realized at system level. This includes, in addition to investigating which solutions are suitable at machine level (new machine concepts adapted to the changed processes, as well as associated charging infrastructure), also the logistics to and from the site, which is now expanded from pure material transport to also include energy transport.

Partner/funder: BTH | Lund University | Volvo Construction Equipment | Swedish Transport Administration

Contact person: Tobias Larsson

Contact

Professor Tobias Larsson

Professor Tobias Larsson

Head of subject, mechanical engineering

E-mail: tobias.larsson@bth.se

Telephone: + 455-38 55 25